Thermal Conversion Facility – Various Task Orders

Woonsocket, Rhode Island

Since 2017, BETA has provided professional engineering services for various task orders within Synagro’s Woonsocket Thermal Conversion Facility.

Project tasks have included:

Turbine & Generator Removal: Synagro required the removal of its existing turbine and generator, which involved the rigging, lifting, and rolling of heavy equipment within the facility where it could be lifted via a crane. This task included evaluation of the existing concrete and structural steel floor and roof framing members to confirm they had adequate capacity to safely execute the proposed rigging operations.

Steam Turbine Generator Room Monorail: Synagro tasked BETA with reviewing the existing structural steel roof framing of the Steam Turbine Generator (STG) room and designing a new steel monorail to support and facilitate the future removal and installation of steam turbine components. A steel monorail system was designed and positioned over the steam turbine to avoid conflicts with existing critical operational elements. BETA prepared a roof framing plan and details showing the layout, connection, strengthening, and/or modifications required for the existing steel members to support the new monorail.

Rooftop Lifting Frame Alterations: Synagro wanted to make alterations to two existing portable rooftop lifting frames for the service and maintenance of existing equipment. BETA performed calculations on the existing lifting frame members to determine if they could be extended vertically to accommodate changed field conditions. BETA provided design calculations, sketches, and details for the lifting frame alternations.

Dewatering/Centrifuge Room Roof Beam Jacking & Support: Two existing butted prestressed concrete beams that make up the roof had been previously cored through and were sagging. The beams’ deflection was interfering with operation of a crane inside the facility’s Dewatering/Centrifuge Room. BETA provided an alternative means of supporting the compromised roof beams, allowing unimpeded operation of the crane. BETA designed and provided details for a new steel frame to support the compromised beams from above and allow crane operations to resume.

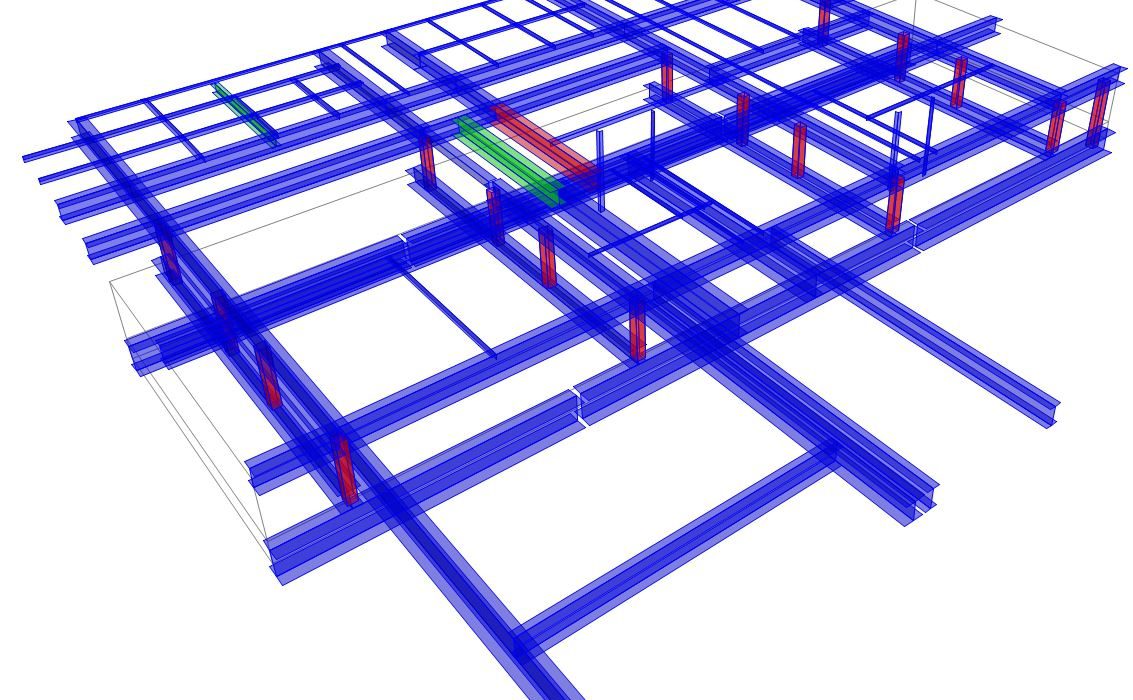

Centrifuge Platform Repairs: The Plant’s Dewatering Room has several operational centrifuges atop an elevated steel platform. Synagro observed that some of the platform members were showing significant signs of deterioration. BETA performed a field inspection of the platform to determine member sizes and shapes, spacing, level of deterioration, and location of centrifuges. With information obtained in the field, BETA developed a 3-dimensional model of the platform to determine its remaining capacity and where critical repairs would be required. Upon completion of the analysis, detailed drawings were provided for the replacement of deteriorated steel members.